稼働を維持する:IGBTシステムにおける予知保全の利点

筆者: Power Integrations、Thorsten Schmidt

予知保全は、運用データを収集・分析し、機器の故障を予兆する異常や動作パターンを特定することで、メンテナンスの頻度を最小限に抑えることを目的としています。この手法を用いることで、故障が発生する前に修復措置を講じるプロセスを構築し、計画外のダウンタイムや不要なメンテナンスコストを回避することができます。

予防保守は、使用状況と時間に基づいて定期的に実施される比較的単純なアプローチです。それは特定の機械の状態が懸念されることを示すデータがある場合にのみ、(メンテナンスの)介入がスケジュールされます。IGBTに着目すると、予知保守は鉄道車両、送電網、風力タービンや太陽光発電所といった大規模な再生可能エネルギー施設といった高価なシステムで採用される可能性が最も高いと考えられます。

Siemens Mobility による鉄道での予知保全に関する研究では、驚くべき結論が導き出されました。

運行中の列車からリアルタイムで収集されるデータにより、正確な保守計画が可能になり、必要な場合にのみ車両基地への帰庫の実現が可能となります。早すぎたり遅すぎたりすることはありません。これにより、予定外の車両基地への帰庫や是正保守の為の介入が最大30%削減されます。

「データに基づいて実行される状態ベースのメンテナンスにより、メンテナンス間隔が延長され、早期の部品交換などの不要な作業がなくなり、メンテナンスコストが最大 15% 削減されます。」

自動測定と状態基準メンテナンス(CBM)インテリジェンスにより、固定間隔ではなく実際のニーズに基づいてメンテナンスをスケジュールできるため、計画外のダウンタイムを常に防止できます。これにより、車両の稼働率は最大100%に達します。

鉄道システムでは、IGBTモジュールとドライバは電力コンバータの寿命に極めて重要です。一部のサプライヤーは、IGBTジャンクション温度に基づいた寿命モデルを提供しています。中電圧および高電圧インバータアプリケーション向けゲートドライバ技術のリーダーであるPower Integrationsは、多くのゲートドライバに他のセンサーに加えて温度レポート機能を搭載しています。

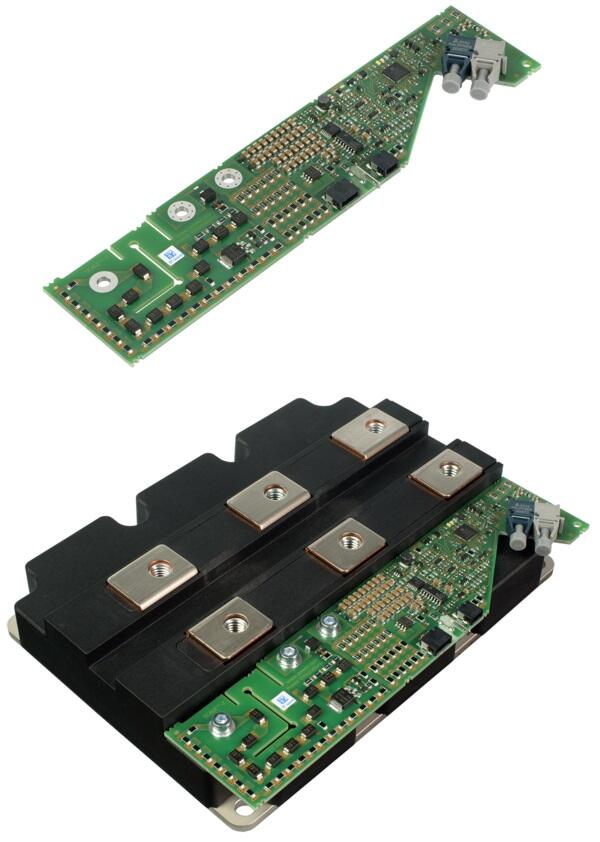

Power Integrations は、鉄道、トラクション インバータ、電力網、中電圧ドライブで使用される最大 3300 V (図 1) の 190 mm x 140 mm IHM および IHV IGBT モジュール用のシングル チャネル、プラグ アンド プレイ ゲート ドライバを提供しています。

シリアルステータス出力プロトコルには重要なリアルタイム計測機能が組み込まれており、高度な動作検証を容易にし、インバータの健全性、信頼性、効率の可視性を大幅に向上させます。エンジニアは、監視・制御システムをPower Integrationsの標準プラグアンドプレイプロトコルに適合させたり、プロジェクトの開発段階でPower Integrationsの専門エンジニアリングチームにカスタム調整を依頼したりすることができます。--

1SP0635 デジタル ゲート ドライバから得られるテレメトリ データには、正確な温度測定機能が含まれており、これにより熱管理が簡素化され、外付け温度センサーが不要になります。データは、Power Integrations 独自のプログラマブル シリアル インターフェースを介して配信され、お客様の要件に応じてプログラム可能です。鉄道市場を席巻する大手企業は、数年にわたって開発されてきた独自のプロトコルを保有しているため、レポート機能の柔軟性が重要です。

現時点では、鉄道、電力網、石油探査など、顧客が 20 年の耐用年数を期待している分野では予知保全ソリューションが真剣に求められていますが、他の業界が、ダウンタイムや緊急メンテナンスを回避し、不必要な介入による余分なコストが発生しないなど、データに基づくメンテナンス手法がもたらすメリットに気付くのは時間の問題です。

また、Power Integrations はすべてのセンシング回路をゲート ドライバ内に統合しているため、顧客のシステム信頼性が向上し、MTBF 評価も向上します。