안전 항해 – 글로벌 확장을 향한 항해에서 전기차를 ‘생존’하게 만드는 방법

최근 몇 년 동안 전기차(EV) 산업은 글로벌 확장에서 눈에 띄는 변화를 겪고 있습니다. 빠르게 성장하는 중국 제조업체들은 대형 운송선에 투자하여 생산 허브에서 전 세계 시장으로 한 번에 수천 대의 신차를 운송하고 있습니다. 이 블로그에서는 대양을 횡단하는 자동차 운송의 성장 규모와 이를 가능하게 하는 혁신적인 기술들을 살펴봅니다.

해상으로 운송되는 차량은 오랫동안 자동차 제조업체들의 글로벌 사업에 중요한 부분을 차지해 왔습니다. 수십 년 동안 토요타와 닛산 같은 기업들은 특수 자동차 운반선을 운영하는 대형 해운사들과의 파트너십에 의존해 왔습니다. 여러 거대 EV 기업들의 부상은 이러한 흐름을 한 단계 더 끌어올리고 있습니다. 이미 세계 최대 EV 제조업체인 BYD는 급증하는 해외 수요에 대응하기 위해 최근에 자체 컨테이너 선단을 출범시켰습니다.

5,000대의 전기차를 실을 수 있는 BYD Explorer No.1을 선보인 지 1년도 채 되지 않아, BYD는 최근 네 번째이자 세계 최대 규모의 차량 운반선을 공개했습니다. BYD Shenzhen호는 길이 219m, 너비 37.7m로, 9,200대의 차량을 해상으로 운송할 수 있습니다. 이 선박들은 중국 북부와 남부 항구에서 유럽 각지로 EV를 정기적으로 운송하며, 글로벌 EV 시장에서 해상 물류의 중요성을 명확히 보여주고 있습니다.

EV 제조업체는 자체 선단을 운영함으로써 제3자 해운사에 대한 의존도를 줄이고, 운송 비용을 절감하며, 수익성을 높일 수 있습니다. 최근 차량 운반선 임대료가 급등한 점을 고려하면, 이는 특히 중요합니다.

컨테이너선을 보유하면 EV 제조업체는 공급망에 대한 통제력을 높일 수 있어, 적시 배송을 보장하고 해운 병목 현상으로 인한 지연 위험도 줄일 수 있습니다. 이러한 통제력은 국제 시장에서 브랜드의 신뢰도와 평판을 유지하는 데 매우 중요합니다.

롤온/롤오프(Roll-On/Roll-Off) 운반선의 역할

차량을 바다 건너 운송하는 데 가장 널리 사용되는 방식 중 하나는 롤온/롤오프(RoRo) 운반선을 활용하는 것입니다. 이러한 특수선은 차량을 선박 위로 직접 올리고 내릴 수 있어, 적재와 하역이 빠르고 효율적입니다. 하지만 이 방식은 수개월에 달하는 항해 기간 내내 차량이 작동 상태를 유지해야 한다는 제약이 있습니다. 이러한 긴 항해는 EV에 독특한 문제를 유발합니다.

배터리 문제

이전 블로그에서 대부분의 순수 전기차가 모든 전기 하위 시스템에 12V 전원을 공급하기 위해 여전히 전통적인 납축전지에 의존하는 이유를 설명했습니다. 내연기관차와 전기차 운전자 모두가 인정하듯, 이러한 구식 배터리는 단 몇 주 만에 방전될 수 있습니다. 리튬 이온 배터리로 교체하더라도, 메인 고전압 트랙션 배터리는 여전히 주기적으로 충전해야 하며, 이 배터리도 수 개월간 선박에 정박해 있을 경우 방전될 수 있습니다.

또 다른 방법은 차량의 메인 고전압-저전압 DC-DC 컨버터를 통해 고전압 배터리 팩에서 전력을 끌어오는 것입니다. 문제는 이러한 컨버터가 저부하 상태가 아닌 풀부하 효율에 최적화되어 있다는 것입니다. 12V 시스템에 대기 전력을 공급할 때 비효율로 인해 상당한 에너지 손실이 발생합니다. 결과적으로, 완전히 충전된 배터리 팩이라도 해상 항해 전체 기간을 견디지 못할 수 있습니다.

완전히 방전된 EV 배터리를 재충전하는 것은 자동차 점프 스타트보다 훨씬 복잡합니다. 장시간 충전소를 이용해야 합니다. 공간과 자원이 제한된 선박 내에서 수천 개의 배터리를 동시에 충전하는 것은 물류 측면에서 악몽과도 같습니다.

솔루션: 파워 인테그레이션스(Power Integrations)의 InnoSwitch3-AQ 플라이백 스위처 IC

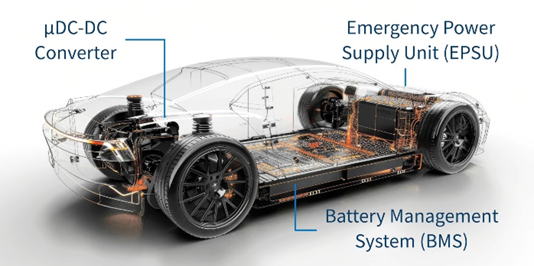

위에서 언급한 이전 블로그에서 파워 인테그레이션스(Power Integrations)의 혁신적인 InnoSwitch3-AQ 플라이백 스위처 IC를 탑재한 마이크로 DC-DC 컨버터 설계를 소개했습니다. 이 견고한 파워 서플라이는 차량의 고전압 배터리 팩에서 안전하게 전력을 끌어올 수 있어, 12V 배터리의 필요성을 없앨 수 있는 시스템을 지원합니다.

이 IC는 부하 범위에서 90% 이상의 효율을 달성하며, 무부하 상태에서는 15mW 미만의 소비 전력을 기록해, 항구, 선박, 차량 정비 센터 등에 얼마나 오래 머물러야 하든 EV 내 모든 12V 시스템이 대기 모드로 유지될 수 있습니다.

InnoSwitch3-AQ 제품군의 새로운 1700V SiC 기반 제품은 800V BEV 시스템을 지원하도록 설계되어 충분한 연면거리를 제공하며, 이에 따라 컨포멀 코팅 없이도 강화된 절연을 달성할 수 있습니다. 최첨단 장치를 사용한 새로운 레퍼런스 디자인은 평면 변압기를 채택하여, 이 12V 배터리 교체 솔루션의 공간 절약 효과를 더욱 향상시켰습니다.

AEC-Q100 인증을 받은 InnoSwitch3-AQ 스위처 IC와 같은 첨단 전력 솔루션의 도입은 EV 산업이 직면한 다양한 문제를 해결하는 데 있어 기술 혁신의 중요성을 강조합니다. 이러한 혁신은 차량 자체의 효율과 신뢰성을 향상시킬 뿐만 아니라, 업계의 글로벌 성장을 뒷받침하는 운송 시스템도 개선합니다.